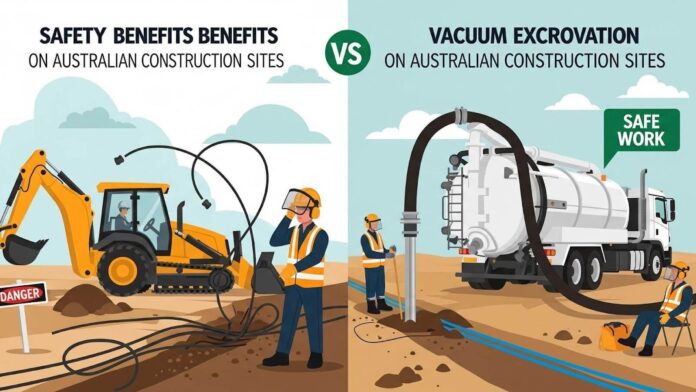

Vacuum excavation has become and remains a trusted method across Australian construction, civil works, utilities and infrastructure projects.

As safety expectations rise and worksites become more congested with underground services, contractors are looking for excavation techniques that reduce risk while maintaining productivity.

Vacuum excavation meets these needs by offering a controlled, precise and highly visible approach to digging that aligns with Australian safety standards and site conditions.

This article explores why vacuum excavation is considered a safer option for Australian construction sites and how it supports better outcomes for workers, assets and project timelines.

Vacuum excavation and non destructive digging in Australia

Vacuum excavation is a non destructive digging method that uses high pressure water or air to loosen soil, which is then removed by a powerful vacuum system.

The material is transferred directly into a sealed debris tank, leaving a clean and accurate excavation.

This method is why it’s prefered over traditional excavation methods when it comes to safely assessing underground utilities.

On Australian worksites, this method is commonly used for service locating, potholing, trenching, pole installation and maintenance around live utilities.

The ability to excavate without mechanical force makes vacuum excavation particularly suitable for urban environments where gas, electricity, telecommunications and water assets are densely packed and often ageing.

Reduced risk of underground service strikes

One of the most significant safety advantages of vacuum excavation is the reduced likelihood of damaging underground services.

Traditional mechanical excavation methods rely on buckets, teeth and blades that can easily strike or rupture buried assets, even when plans and locating tools are used.

Vacuum excavation allows operators to expose services gradually and visually, reducing the chance of accidental contact.

This is critical on Australian sites where a single service strike can lead to serious injury, service outages, environmental harm and substantial financial penalties.

By using vacuum excavation, crews gain greater confidence when working near live assets.

Improved worker safety on site with hydro vacuum excavation

Construction remains one of Australia’s highest risk industries, with Safe Work Australia consistently highlighting the dangers associated with plant operation, manual handling and underground works.

Vacuum excavation directly addresses several of these risk areas.

Lower exposure to heavy machinery hazards

Vacuum excavation reduces the need for workers to be close to moving mechanical plant.

The excavation process is typically controlled from a safe distance, with hoses extending into the dig area while the truck remains stationary.

This separation helps minimise risks associated with crush injuries, struck by incidents and equipment entanglement.

In many cases, fewer personnel are required in the immediate excavation zone, which further improves site safety and simplifies traffic and pedestrian management.

Enhanced stability of excavation areas

Because vacuum excavation removes soil in a controlled and targeted manner, it is less likely to undermine surrounding ground.

This helps maintain the stability of trenches and pits, reducing the risk of collapses or any disasterous potential cave ins.

For Australian sites dealing with variable soil types, from sandy coastal ground to reactive clays, this controlled approach offers a more predictable outcome.

Better visibility and control during excavation

Vacuum excavation provides operators with excellent visibility throughout the digging process.

Soil is removed layer by layer, allowing crews to identify changes in ground conditions and locate assets as soon as they appear.

This level of control is especially valuable on Australian projects where undocumented services are common, particularly in older suburbs and regional areas.

Early identification allows work to slow or stop immediately, preventing damage and enabling safer decision making.

Reduced need for manual digging

Manual hand digging has traditionally been used around sensitive services, but it presents its own safety risks including musculoskeletal injuries and prolonged exposure to hazards.

Vacuum excavation significantly reduces the need for manual excavation, helping protect workers from strain, fatigue and repetitive injuries.

Safer outcomes in challenging environments

Australian construction sites often face environmental and logistical challenges such as extreme heat, tight access, live traffic and active public spaces.

Vacuum excavation adapts well to these conditions.

The ability to excavate from a distance means less disruption to surrounding areas, which is particularly important on road projects and in built up environments.

Reduced spoil on the ground also lowers slip and trip hazards, contributing to a cleaner and safer site overall.

Compliance with Australian safety expectations

Australian regulators and principal contractors increasingly favour methods that demonstrate proactive risk reduction.

Vacuum excavation aligns with these expectations by offering a documented, widely accepted approach to safe digging.

Many companies now specify vacuum excavation in their safe work method statements and project requirements, recognising its role in injury prevention and asset protection.

Long term safety benefits for projects and businesses

Beyond immediate site safety, vacuum excavation supports long term risk management for construction businesses.

Fewer incidents mean fewer delays, claims and investigations.

Protecting underground assets also helps maintain positive relationships with utility providers and clients, which is essential in Australia’s tightly regulated construction environment.

When safety performance improves, so does workforce morale. Crews who feel protected by the right tools and methods are more engaged and productive, contributing to better project outcomes.

Why vacuum excavation continues to gain momentum

Vacuum excavation is no longer viewed as a niche solution.

Across Australia, it is becoming a standard practice for works that involve underground services or sensitive ground conditions.

Its safety advantages, combined with efficiency and accuracy, make it a smart choice for modern construction sites.

As projects grow more complex and expectations around safety continue to rise, vacuum excavation offers a proven way to reduce risk while maintaining control and confidence on site.